Validation and pre-series of moulds for plastic materials

Tecnostampi invests a lot in innovation and continuous improvement of the production process. The company employs qualified and skilled staff in order to offer full service and a series of processes carried out with a modern and technologically advanced machine park.

Tecnostampi designs and manufactures injection moulds and creates products that are increasingly advanced from a technical point of view, capable of responding to the changing needs of companies in different industrial sectors, from automotive to medical, electronics and packaging.

In our company, a first-rate technical staff follows the product at every stage of design, production and assembly. Services also include validation and pre-series of plastic items as well as pre and post sales assistance that is always customized and efficient.

Mould manufacturing: our services

The flagship of Tecnostampi is no doubt the design office, where our technicians carry out the study of the product and equipment to be made, collaborating with the customers and interpreting their needs in order to develop high-performance and efficient solutions.

Before starting the design, manufacturing and validation and pre-series of the moulds for plastic materials, the staff of Tecnostampi carry out a feasibility study to evaluate and examine the critical issues of the products in advance and possibly also propose a co-design of its adjustments. This type of study can help optimize the manufacturing, moulding and mould pre-series process.

The design area of Tecnostampi is supported by Cimatron, SolidWorks, TopSolid CAD stations equipped with an interface to read any format.

Tecnostampi has a programming department with competent technicians that, with the support of Cimatron, Autodesk, Fikus CAM stations, coordinates CNC machines of high quality standards.

The workshop department is also fundamental in Tecnostampi:

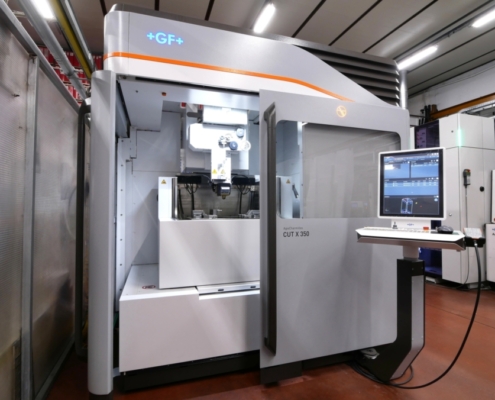

To keep up with the times, Tecnostampi has invested in INDUSTRY 4.0 in particular by installing a brand new Agie Charmilles platform consisting of two fully automated sinking- and wire-electroerosion working stations served by Erowa robots managed directly by the programming unit. Then there are 200 electrodes and 20 pallet stations inside the two big warehouses.

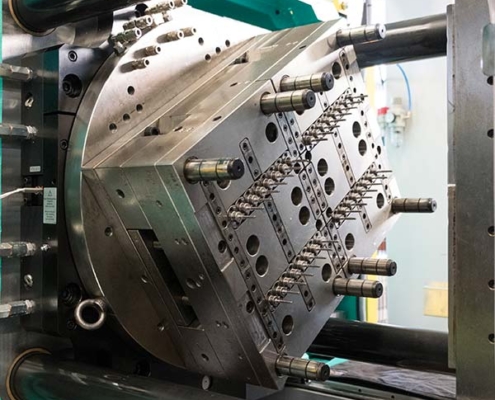

After the manufacturing, we proceed with the validation and pre-series of the injection moulds. Tecnostampi staff are always available for advice and after-sales assistance for customers.

Tecnostampi has ARBURG, ENGEL from 50t to 350t and two-component ARBURG injection machines to guarantee the validation and pre-series of injection moulds.

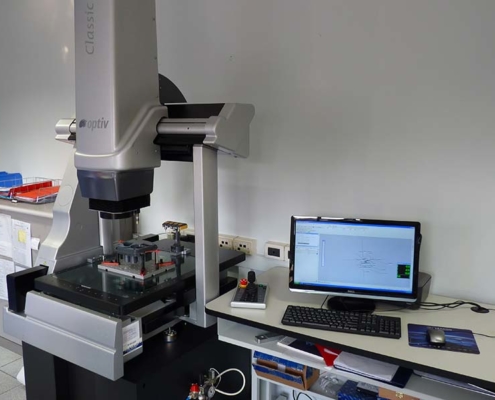

Each press is robotic and is monitored and checked by our Quality Control department that uses a wide range of tools including a Hexagon Optiv Classic 453 for dimensional check of the moulded products.

Testing the moulds internally is a service that allows Tecnostampi to prove the customer the good quality of the design and the perfect functionality of the mould.